Advanced Smart Manufacturing Systems

highlight_off

The project

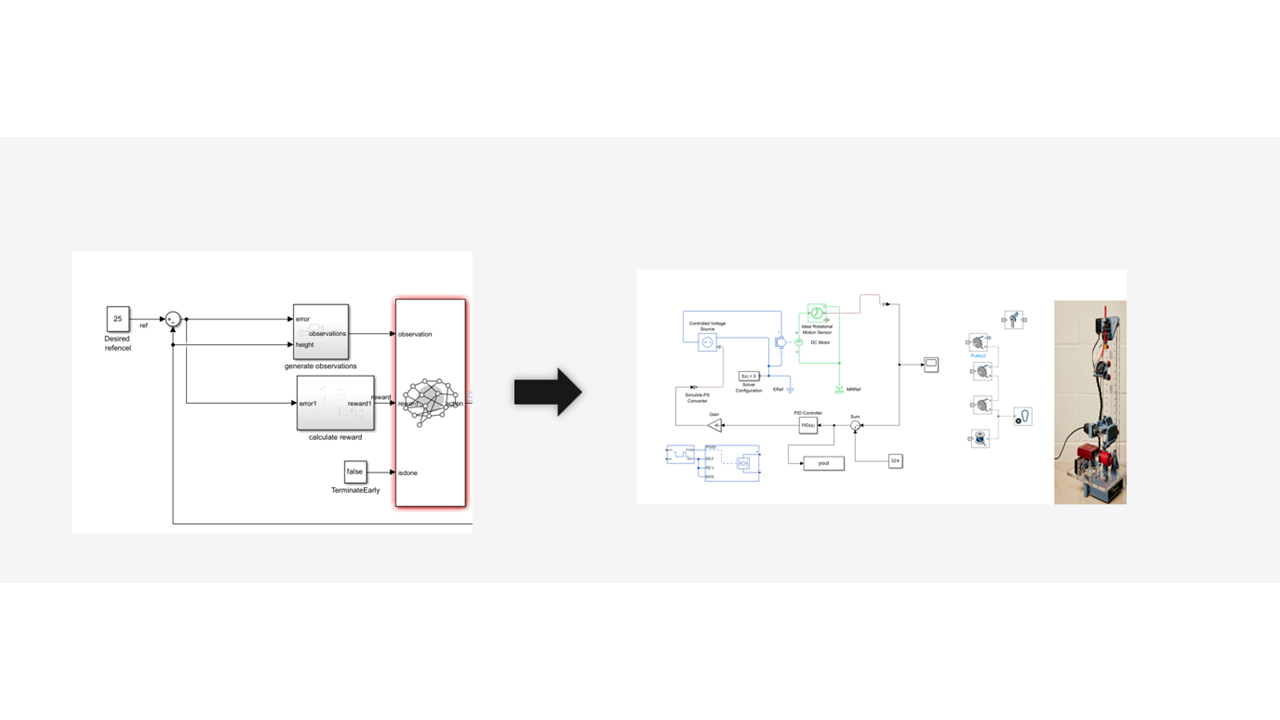

focuses on the development and implementation of advanced manufacturing systems

that integrate cutting-edge technologies to enhance overall performance and

efficiency. Modern manufacturing is no longer defined by isolated processes;

instead, it relies on the seamless combination of artificial intelligence,

control systems, sensors, instrumentation, and digital platforms.

This

initiative seeks to design, elaborate, and validate a manufacturing framework

in which these technologies converge to create a highly responsive,

data-driven, and intelligent production environment. Through real-time

monitoring, predictive control, and advanced analytics, the project will enable

improved decision-making at every stage of the manufacturing process.

The

expected outcome is a transformation of conventional manufacturing practices

into systems that are more productive, efficient, and adaptable. By reducing

variability, improving quality, and strengthening the capacity of manufacturing

systems to respond to dynamic requirements, this project establishes a scalable

foundation for the integration of future technological advancements.

Ultimately, it demonstrates how advanced technologies, when strategically

combined, can create smart, sustainable, and resilient manufacturing s5

products that meet the demands of Industry 4.0 and 5.0.

Responsibilities

and Work Plan

The student

assigned to this project will play a central role in the technical design,

deployment, and validation of the proposed advanced manufacturing system. Their

responsibilities will begin with the conceptual and detailed design of the S5 framework,

ensuring that artificial intelligence models, control strategies, and sensor

networks are correctly specified and aligned with the project objectives. The student

will also be responsible for translating these specifications into the functional

prototype, integrating digital tools with physical manufacturing equipment, and

establishing reliable data acquisition and monitoring protocols.

Once the

initial proposals are ready, the student will lead his deployment in the

manufacturing system, overseeing installation, calibration, and configuration

of both hardware and software components. A critical part of this

responsibility will be validating system performance, which involves designing

and conducting experimental trials, analyzing results against expected

benchmarks, and making iterative adjustments to enhance the efficiency,

reliability, and adaptability of the solution.

The general

work plan will follow a structured sequence. In the design phase, the student

will develop system models and integration schemes that define the

technological architecture. In the deployment phase, they will implement these

models into a real or pilot-scale manufacturing environment, ensuring smooth

interoperability between digital and physical layers. The validation phase will

focus on testing and refining the solution through experimental data,

identifying strengths and limitations. Finally, in the assessment and reporting

phase, the student will document outcomes, propose improvements, and provide

recommendations for scaling the solution to broader manufacturing contexts.

Through

this structured set of responsibilities, the student will ensure that the

proposal is not only theoretically sound but also practically validated within

the system, creating a foundation for advanced, efficient, and sustainable

manufacturing practices.

10

Pedro Ponce

pedro.ponce@tec.mx

Artificial Intelligence

Manufacturing Systrems

Control Systems

Product design

Automation

warning

error_outline

Formacion academica anterior

50 %

Motivación

10 %

Formación en escritura y lectura tecnica

20 %

Expresión oral

20 %

:

circle

circle

circle

circle

circle