Hydrogen SNRGY initiative Green Hydrogen Generation by Electrolysis Using 3D-Printed Electrodes

highlight_off

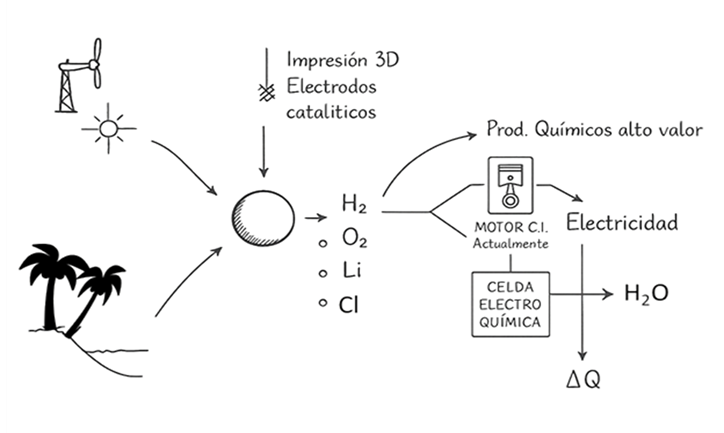

The Hydrogen SNRGY Initiative addresses the global need for sustainable and scalable solutions to produce clean hydrogen, a crucial component in the energy transition. Conventional water electrolysis technologies face limitations in terms of efficiency, cost, and durability, particularly due to electrode design and the challenges of managing gas bubbles during high-current operation. Our project proposes an innovative pathway that integrates additive manufacturing, advanced coatings, and electrochemical activation to develop next-generation electrodes capable of unlocking higher performance at reduced cost.

The core of the initiative is the fabrication of three-dimensional porous electrodes via 3D printing using conductive and polymer–graphite composite substrates. These printed scaffolds are subsequently coated with active metallic layers such as nickel, cobalt, or nickel–iron alloys through controlled electrochemical deposition. By tailoring the electrode geometry and surface properties, the design promotes efficient charge transfer, enhances the electrochemical surface area, and mitigates gas bubble accumulation, which are critical factors in improving the kinetics of the hydrogen evolution reaction (HER) and the oxygen evolution reaction (OER).

Preliminary results demonstrate uniform metal deposition, stable alkaline operation, and promising hydrogen generation rates under laboratory conditions. Through cyclic voltammetry, impedance spectroscopy, and linear sweep voltammetry, we have confirmed the electrochemical activation of the electrodes and the improvement of catalytic activity. These findings validate the feasibility of combining additive manufacturing with wet chemistry techniques to achieve scalable electrode architectures optimized for water electrolysis.

Beyond the technical advances, the Hydrogen SNRGY Initiative contributes to a circular and sustainable vision by enabling the use of low-cost, customizable materials and minimizing reliance on critical noble metals. The project also emphasizes interdisciplinary training of young researchers and collaboration with academic and industrial partners to accelerate technology readiness.

Our long-term objective is to bridge the gap between fundamental electrochemical studies and pilot-scale demonstrators, advancing towards a hydrogen economy that supports decarbonization in key sectors, including mobility, industrial processes, and renewable energy integration. The Hydrogen SNRGY Initiative positions itself as a catalyst for innovation, offering a disruptive approach to green hydrogen generation through the synergy of 3D printing, materials science, and electrochemistry.

The Hydrogen SNRGY Initiative is structured around an integrated plan that combines advanced experimental work with continuous scientific dissemination and knowledge generation. Responsibilities are organized into three interconnected pillars:

-

Literature Review and Knowledge Integration

A systematic review of state-of-the-art research on green hydrogen production, 3D-printed electrodes, and electrocatalytic materials will be conducted. This process ensures the identification of current challenges, benchmarking of performance metrics, and mapping of technological gaps. The review also provides the conceptual foundation for designing electrode architectures, selecting coating strategies, and aligning the project with international trends in hydrogen technologies. -

Scientific Writing and Dissemination

Regular preparation of high-quality manuscripts for peer-reviewed journals and conference proceedings will be carried out. Emphasis will be placed on generating impactful contributions that document both methodological advances and application-oriented results. The plan includes drafting review papers to consolidate knowledge, as well as original research articles reporting electrochemical characterization, material design, and performance evaluation. Dissemination through international conferences, workshops, and invited talks will strengthen the project’s visibility and impact. -

Experimental Development and Validation

The experimental component is the backbone of the initiative. It involves the design and fabrication of 3D-printed electrodes using conductive polymer–graphite composites, followed by metallic coating (Ni, Co, NiFe, MoNi) via electrochemical deposition. Systematic electrochemical characterization (CV, LSV, EIS, OCP) will be performed to quantify catalytic activity, electrochemical surface area, roughness factors, and gas bubble management. Iterative optimization of geometry and coating will enable a feedback loop between experimental results and modeling. Pilot tests under alkaline conditions will validate electrode stability and hydrogen generation efficiency.

By integrating these responsibilities, the Hydrogen SNRGY Initiative establishes a next-generation scientific workflow where experimental innovation is complemented by critical analysis of the literature and continuous scientific communication. This holistic plan ensures both technological progress and knowledge dissemination, accelerating the pathway toward scalable green hydrogen.

40

Manuel Alejandro Ávila López

avila.manuel@tec.mx

3D print

Electrolysis

Green H2

warning

error_outline

Publicación

100 %

:

circle

circle

circle

circle

circle