High throughput Nano-encapsulation

highlight_off

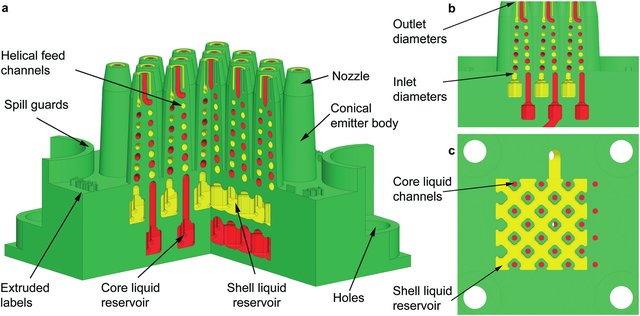

This project focuses on coaxial electrospray, an electrohydrodynamic technique that enables the fabrication of core-shell microparticles by atomizing a charged liquid jet. The method allows for precise encapsulation, producing particles with narrow and tunable size distributions.

Such control is critical for a range of advanced applications, including:

-

Targeted drug delivery

-

Self-healing materials

-

Functional coatings for food and solar cells

By joining this project, the student will contribute to the development and optimization of this cutting-edge technology and gain hands-on experience in microfabrication, additive manufacturing, and process modeling.

As part of this research experience, the student will:

-

Design microfluidic devices using SolidWorks, tailored for stereolithography (SLA) 3D printing.

-

Optimize SLA printing parameters to achieve high-resolution microchannel fabrication.

-

Explore and refine electrospinning/electrospray deposition settings to enhance process control.

-

Collect, process, and analyze experimental data to support the development of a mathematical model describing key process variables.

8

Daniel Olvera Trejo

daniel.olvera.trejo@tec.mx

additive manufacturing

electrospray

coaxial electrospray

warning

error_outline

:

circle

circle

circle

circle

circle